Stability in turbulent times

Perseverance, measured action, regional roots:

These three strengths symbolize our company's development. They have carried us through the post-war years, the sword of Damocles that was nationalization, the planned economy, the fall of the Berlin Wall, and various crises.

The once small family-run company has transformed itself into an innovative medium-sized business. Despite all the external changes, we have remained true to ourselves for more than 70 years: UNGER Kabel-Konfektionstechnik GmbH is and will remain a family-owned company.

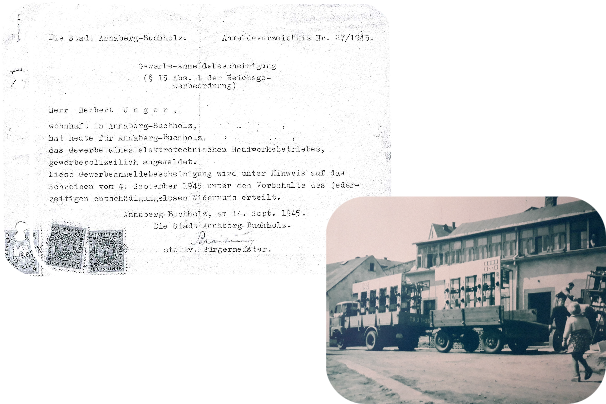

1945

On September 14, 1945, Herbert Unger registers an electrical engineering workshop with the city of Annaberg-Buchholz.

1948

Renamed “Sühnel und Unger.” Richard Sühnel joins as a partner.

1961

Richard Sühnel dies. Werner Unger, the founder's brother, takes over the commercial side of the business.

1972

Last nationalization campaign by the SED government in the GDR. In order to survive as a family business, the mechanical engineering division is forced to transfer to the mining company SDAG Wismut. UNGER Kfz-Elektrik does not survive.

1974

Horst Unger, son of the company founder, continues to run the business as UNGER Elektroanlagenbau. The once flourishing company was involuntarily reduced to 12 employees.

1991

Seizing an opportunity: Entrepreneurial foresight leads to growth and the founding of UNGER Elektro-Anlagenbau GmbH.

1992

Horst Unger passes away. His wife Ursula and his sons Heiko and Ronny take over the management of UNGER Elektro-Anlagenbau GmbH with 15 employees.

1998

UNGER reaches the next level: founding of the industrial manufacturing company UNGER Kabel-Konfektionstechnik GmbH.

1999

Start of production in the new building

2001

Purchase of a disused industrial property in Sehma

2006

Completion of the fundamental renovation of Plant 2. The building complex is a modern industrial complex, an architectural eye-catcher, and a commitment to the company's roots.

2008

New extension building in Cranzahl to create Plant 3 for our special machine construction and machining

2011

UNGER establishes its own research and development department

2016

Commissioning of fully integrated production of power cords for electric toothbrushes

2017

Start of production at the Chemnitz manufacturing site

2018

Commissioning of a fully automated high-bay warehouse

2019

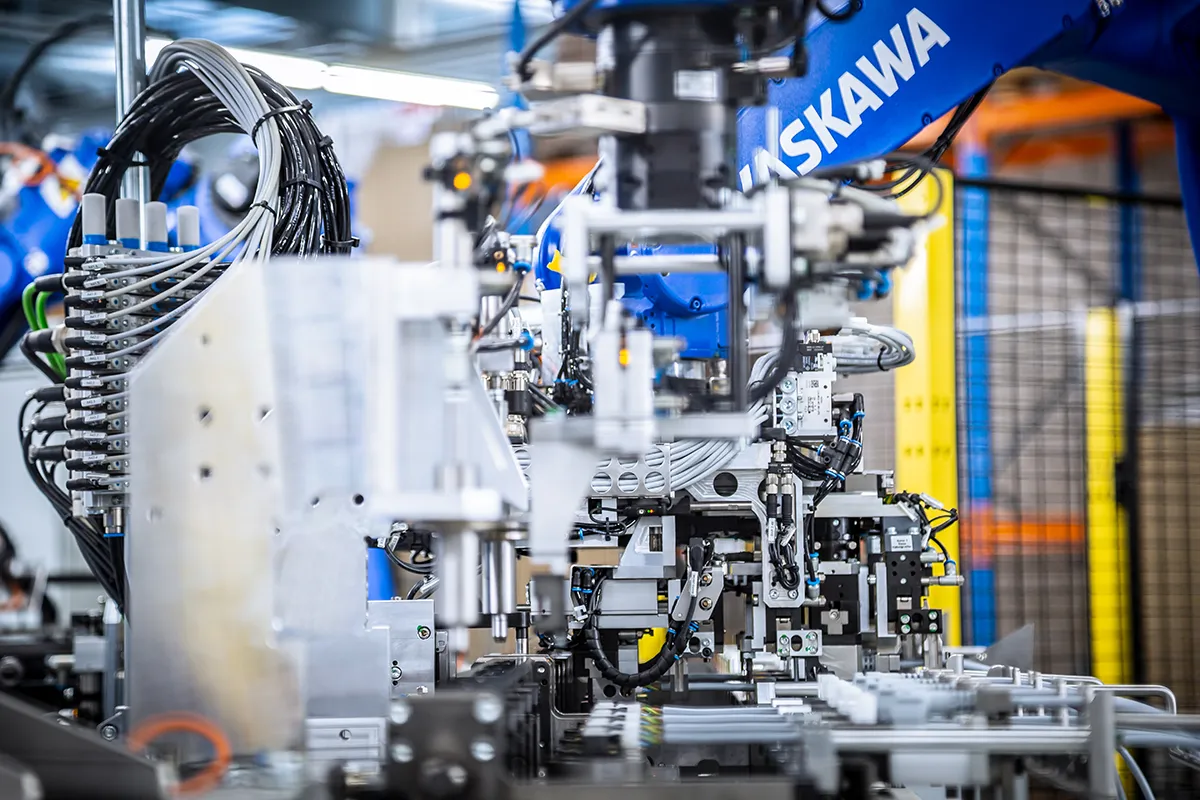

Expansion of capacities to include in-house PVC cable extrusion. At the same time, first fully automated cable harness laying using handling robots.

2020

UNGER increases its performance at the Chemnitz site. Focus: Fully automated cable assembly in fully interlinked production

2023

Creation of additional capacity at the Sehma site. Focus: Fully automated cable assembly in fully interlinked production