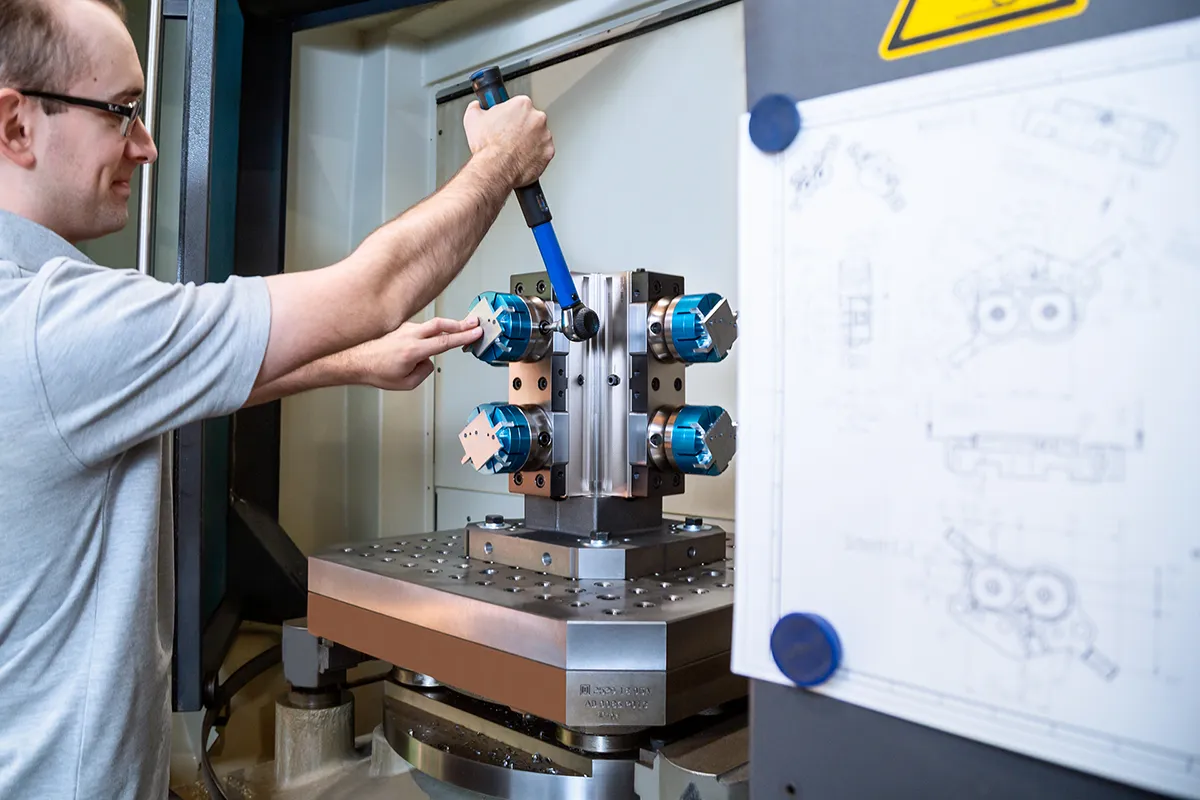

CNC machining: Top quality, made to measure

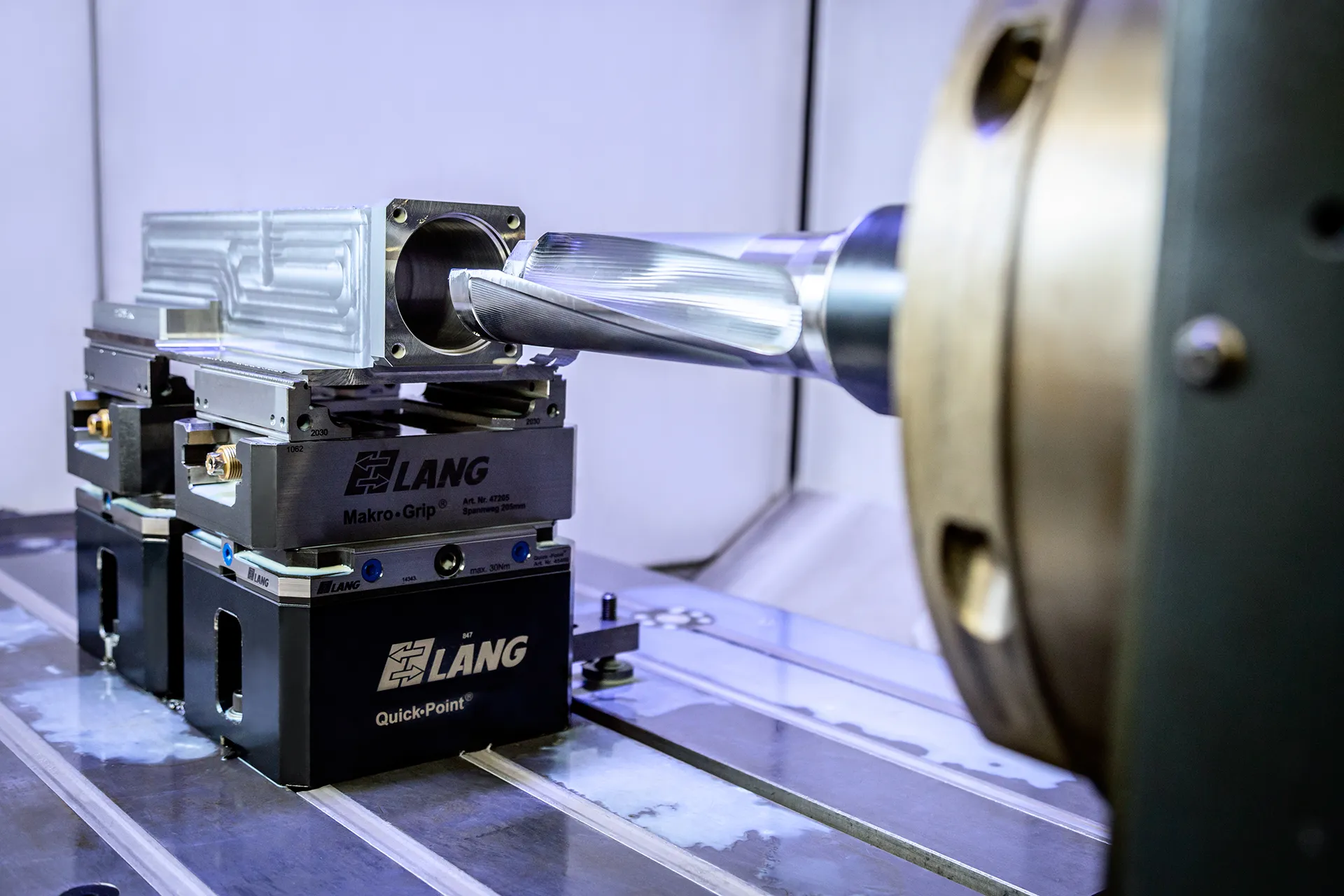

Your product is the benchmark. Whether it's a prototype, a custom solution, or a series production part, UNGER manufactures almost any component from all machinable materials.

This email address is being protected from spambots. You need JavaScript enabled to view it.

Process optimization?

We can do that.

You can find everything relevant to CNC machining/milling/turning here:

Range of services offered by the machine park

Quantities/number of items

UNGER operates as a traditional processor. This means that we also supply custom-made products. CNC machining/milling/turning is primarily designed for larger quantities, including over 100,000 units per year.

Data transfer CAD/ CAM

Intelligent data management saves time and unnecessary queries. For programming, we require files in these formats:

- STEP

- IGES

- Solid Edge

- DXF

- DWG

- Parasolid

Are you using other formats? Ask us!

Additional processing

UNGER always thinks one step ahead. We offer the following additional services in-house:

- Band saw cutting

- Vibration grinding

- Washing

- Surface grinding

Your advantage: Streamlined processing. Shorter delivery times.

Everything from a single source.

Local for Local Sourcing

People work with people. The UNGER network includes service providers from the region. Almost all of them are located within a 40-kilometer radius. Benefit from the portfolio and proximity of our partners:

- Flame, laser, and water jet cutting

- Casting, forming, heat treatment

- Cylindrical grinding

- Honing

- Powder coating, electroplating

- Burnishing, anodizing

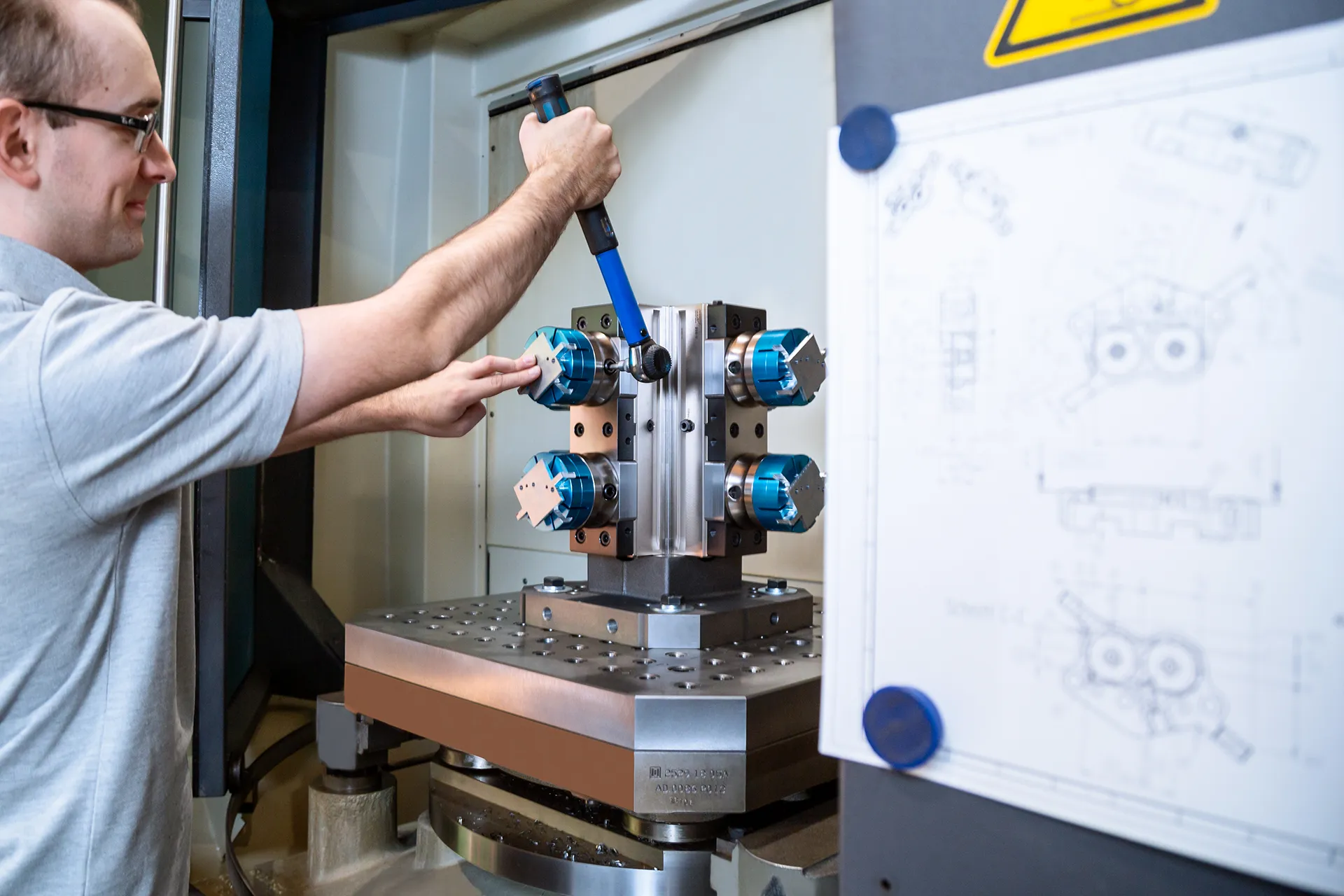

Quality. Of course!

Every part undergoes the UNGER testing process before delivery. State-of-the-art measuring and testing technology and a team of ambitious technicians guarantee precise results. We will be happy to send you initial sample test reports, measurement reports, etc.!

Why choose UNGER CNC machining?

UNGER stands for one thing above all else: expertise. When a component truly “breaks the mold”, our team rises to the occasion.

Why? Our background was and is special-purpose machine construction. Complex CAD or CAM programming is therefore part of our expertise.

This email address is being protected from spambots. You need JavaScript enabled to view it.